3phase power transformers

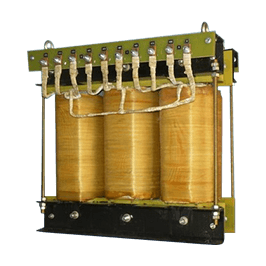

3 Phase Electrical Power Isolation Transformer

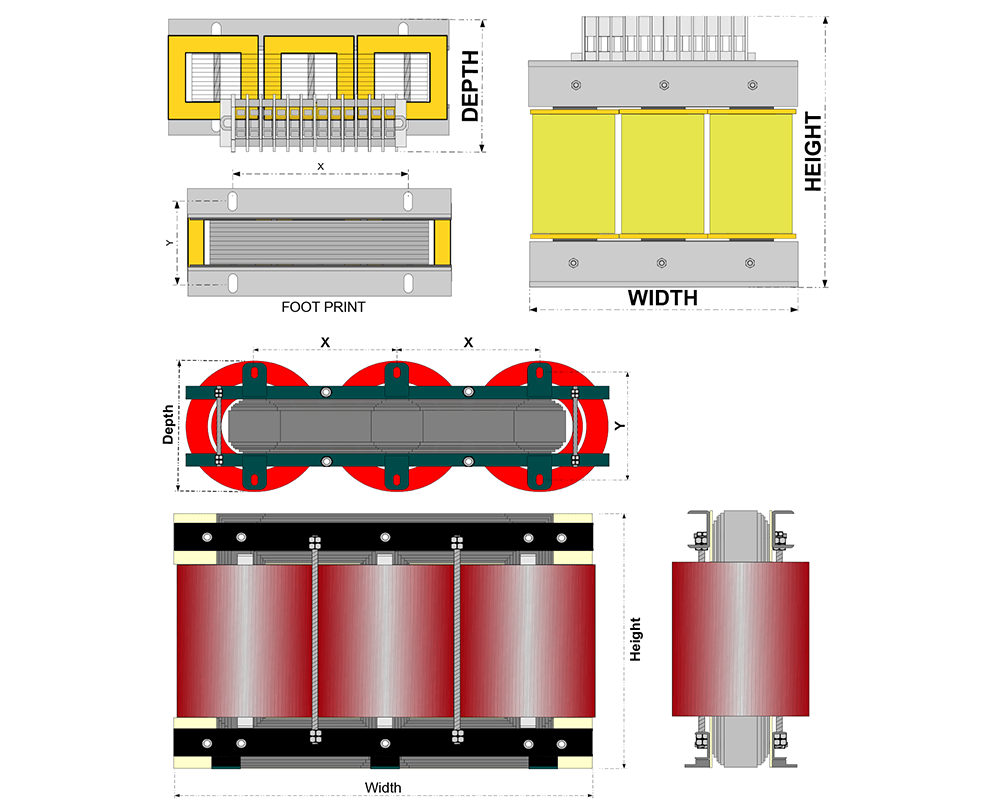

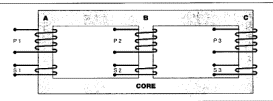

A 3 phase transformer, there is a three-legged iron core as shown below. Each leg has a respective primary and secondary winding. Thus a 3 phase isolation transformers is a 3 phase transformer which has isolated primary and secondary windings to allow the power input to be isolated from the power output.

Standard 3 Phase Isolation Transformers

3 phase isolation transformers have 3 primary and 3 secondary windings that are physically separated from each other. Sometimes these isolation transformers are referred to as "insulated". This is because the windings are insulated from each other.

In a 3 phase isolation transformer the output windings will be isolated, or floating from earth ground unless bonded at the time of installation.

3 Phase Transformers Overview

3 phase transformers are used throughout industry to change values of 3 phase voltage and current. Since 3 phase power is the most common way in which power is produced, transmitted, an used, an understanding of how 3 phase transformer connections are made is essential. In this section it will discuss different types of 3 phase transformers connections, and present examples of how values of voltage and current for these connections are computed.

3 phase Transformer Construction:

A 3 phase transformer is constructed by winding three single phase transformers on a single core. These transformers are put into an enclosure which is then filled with dielectric oil. The dielectric oil performs several functions. Since it is a dielectric, a nonconductor of electricity, it provides electrical insulation between the windings and the case. It is also used to help provide cooling and to prevent the formation of moisture, which can deteriorate the winding insulation.