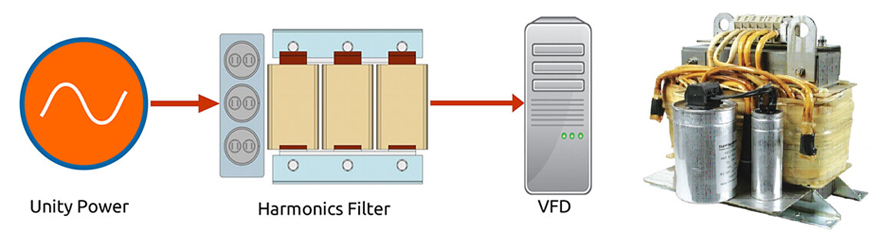

Sine Wave Filter

Best-in-class SineWave Filter for cleaning PWM output from VFD.

- Increases motor life

- Protection of Motor cable & connected Load equipment

- Easy to install and service.

- Operates in high ambient temperatures.

- High performance and reliability.

Output of all VFD having PWM waveform with high frequency and voltage peak. It will damage Motor, Cable and connected Load equipment. Prima Transformers Pvt Ltd designed Sine Wave Filters transform the output of Variable Frequency Drives (VFDs) to a near perfect sinusoidal waveform for the best level of motor protection. Prima’s unique, design offers high performance with smaller size and better efficiency than traditional LC Filter.

The Sine Wave Filter also offers incredible reliability and durability. It is more efficient and tolerates higher ambient temperatures, making it ideal for a variety of applications from steel mills to oil fields. Its modular design and smaller footprint make it easier to integrate and install.

Increase motor life: Reduce motor heating through reduction of high frequencies associated with VFD output and also reduce motor insulation stress through reduction of motor peak voltages.

Reduce motor audible noise:Reduce audible noise through reducing high frequencies associated with VFD output. Reduce radiated emissions: Reduce emissions through reducing high frequencies associated with VFD output.

Protect your motor cable: The reduction of high frequencies associated with VFD output eliminates the need for special motor cables.